Motor Mounts

Enhancing Engine Performance: Motor Mount

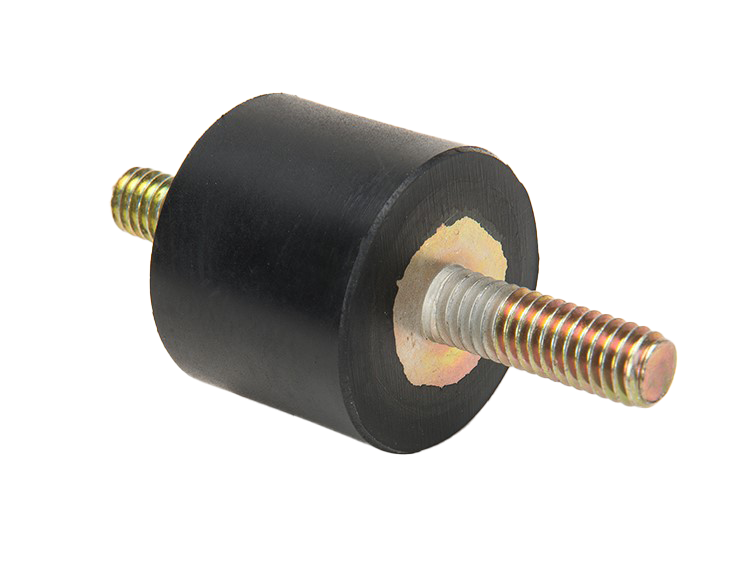

Motor Mounts

Motor mounts stand as the unsung heroes of the automotive world, silently ensuring the smooth operation of vehicles while absorbing the vibrations and shocks generated by powerful engines.

- Engine Stability and Alignment: The purpose of motor mounts is to ensure that the engine stays securely within the chassis of a vehicle. They provide crucial support to the engine, preventing excessive movement or shifting during acceleration, braking, and cornering. Proper engine alignment is essential for optimal performance, fuel efficiency, and vehicle dynamics.

- Vibration and Noise Isolation: One of the primary functions of motor mounts is to minimize the transmission of engine vibrations and noise to the vehicle's cabin. During operation, engines generate vibrations that can cause discomfort for passengers and lead to premature wear and tear on vehicle components.

- Enhanced Driving Comfort: Motor mounts contribute to a smoother and more comfortable ride for drivers and passengers by dampening engine vibrations and isolating noise. The absence of excessive engine noise and vibrations allows occupants to enjoy a more relaxed and enjoyable driving experience, particularly during long journeys or rough road conditions. Lusida Rubbers understands the importance of driving comfort and prioritizes the development of motor mounts that enhance the overall ride quality of vehicles across diverse applications.

- Durability and Longevity: Motor mounts are subjected to constant stress and strain due to the dynamic forces generated by the engine and the rigors of daily driving. We utilize high-quality materials and rigorous testing protocols to ensure that their motor mounts withstand the demands of real-world driving conditions, providing reliable performance and extended service life for vehicle owners.

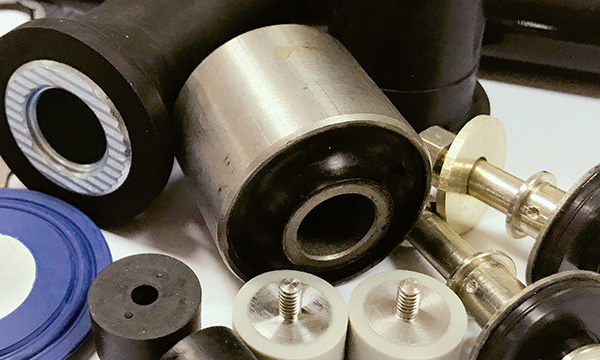

- Customization and Innovation: Lusida Rubbers recognizes that different vehicles and applications may require unique motor mount solutions. As a result, they offer customizable options to meet their customers' specific requirements. Whether it's adapting to different engine configurations, accommodating space constraints, or addressing performance demands, we leverage our expertise in rubber molding to deliver innovative motor mount solutions tailored to individual needs.

Lusida Rubber Products' Expertise

Lusida Rubber Products specializes in utilizing its advanced manufacturing capabilities and expertise to manufacture top-notch motor mounts customized to meet the unique requirements of various vehicle models and applications. Our motor mounts guarantee optimal performance and dependability even in varying driving situations by emphasizing precision engineering and creative design.

Applications Across Industries

Lusida rubber's motor mounts find applications in the automotive industry and in various other sectors.

- Marine Applications

- Industrial Machinery

- Agricultural Equipment

- Construction Machinery

- Power Generation

- Commercial Vehicles

- Off-Road Vehicles