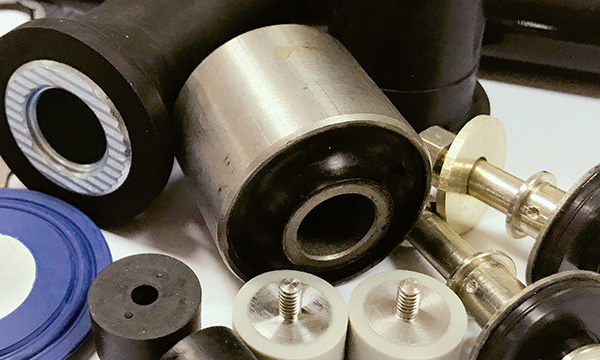

Rubber Bushings

Rubber bushing, along with mounts and isolators, are components that cushions and dampens any vibrations, shocks, or noise from movable parts or the machine itself. Rubber is often used for the bushing because of its elasticity, durability, and unique ability to withstand different environmental conditions.

Construction and Materials

Rubber bushes are generally made from multiple layers of rubber in which the inner metal or metal sleeve is bonded. The rubber used in tyres can vary based on what is needed for the specific use. The metal sleeve acts as a reinforcing element, and it can provide structural integrity and support to the rubber component. It also assists in jointing bushing with other mechanical parts of or within the system.

Our Features

Lusida Rubber Products stands for quality and the latest know-how in manufacturing rubber features, including rubber bushings. With over 25 years of service and certified quality, Lusida Rubber Products is a deserving partner for standard and custom rubber part orders across industries. Our dedication to excellence in innovation and customer satisfaction guarantees that each rubber bushing we manufacture is the best in quality, performance, and popularity. Lusida Rubber Products utilizes an array of materials and the most advanced manufacturing methods to fulfill the needs of its customers, which is continuously evolving in that it offers reliable and competitively priced manufacturer solutions, even for the most demanding engineering applications.

Rubber Bushings Applications

Rubber bushings find widespread use across a diverse range of industries and applications, including:

- Automotive Industry: Suspension systems, engine mounts, control arms, and sway bars get isolated from vibrations and noise by rubber bushings in vehicles that enhance ride quality and improve overall performance and comfort.

- Industrial Machinery: In industrial environments, rubber bushings are used for machinery, equipment, and heavy-duty applications to work as shock absorbers and reduce vibrations by preventing metal-to-metal contact, thus enhancing the lifetime of components and guaranteeing smooth operation.

- HVAC Systems: Bumpers and buffers made of rubber are commonly used in HVAC systems to reduce noise transmission, filter out compressor vibrations, and improve system efficiency and reliability.

- Electronics and Appliances: Rubber bushings are inserted in electronic devices, household appliances, and consumer goods to prevent noise, vibration, and impact – therefore, if the item is operated, no extra loud noise is generated, and the products last longer.

Benefits of Rubber Bushings

The use of rubber bushings offers several key benefits:

- Vibration Isolation: The rubber bushings can absorb and dampen the vibrations, which ensures that these vibrations are not propagated to various systems or structures in the surroundings, leading to less noise and increased operational stability.

- Noise Reduction: Using rubber components, such as bushings, helps reduce noise from the many parts or machines by accepting and acting off mechanical vibrations, which ensures a quieter working environment and, hence, a better user experience.

- Shock Absorption: Rubber bushes are installed to dampen shock, absorb impacts and help protect sensitive components from damage or premature wear, thus improving equipment reliability and safety.

- Flexibility and Versatility: Rubber bushings are of different types, including but not limited to shapes and configurations that can be manufactured to fit the required design.

- Importance in Engineering: Rubber bushings act as a critical core component for modern engineering applications through the functionalities of vibration isolation, noise reduction, and shock absorption. Their adaptability, robustness, and reliability make them necessary add-ons in automotive, industrial, and consumer applications, mainly when unimpeded running and feeling are essential.

Why Choose Lusida Rubber Products ?

- Innovation and Expertise: Lusida Rubber Products is a company that places innovation and constant implementation aims as its core pillars. Technology is paramount to us, and most of the time, a highly regarded standard in the industry is good enough for us to gain ground. We are home to a team of seasoned experts with years of know-how and up-to-date market perception. We dedicate ourselves to supplying the industry requirements with the constant improvements of our services.

- Customization and Flexibility: Lusida Rubber Products are perfectly customized, allowing clients to create rubber bushings to suit their specifications and unique application needs. Whatever critical issues it may be: material, design, or production scale - we have a cost-effective and high-quality solution for a particular customer case.

- Comprehensive Product Range: Besides the rubber bushings, Lusida Rubber Products can provide a broad selection of rubber components, including O-rings, gaskets, seals, molded rubber parts and the rest. Our rubber, plastic, and metal finished and primary or semi-raw products fulfill the multiple needs of the generation, thus making us a one-stop solution organization.

- Cost-Effective Manufacturing: Lusida Rubber Products is a mission-driven business delivering the best to its customers. We strive to achieve cost-effective solutions using strict manufacturing processes, high-quality control measures and competitive pricing. Our solutions are uncompromising regarding quality or reliability.

RUBBER BUSHING

Lusida Rubber Products hereby introduces itself as a trusted supplier of high-quality rubber bushings which are specific for the purpose of optimizing performance and reliability across broad applications. Through our innovative technology, precision engineering and top quality materials, we provide tailored solutions to cater to the different needs of the various industries around the world.

What are Rubber Bushings?

The rubber bushings are highly viable in many mechanical systems acting as a cushion, vibration isolator and a noise reducer. The flexible components, on their part, act as a shock absorber between movable parts and also contribute to reducing friction thereby increasing efficiency and lifespan.

- Precision Engineering for Optimal Performance: Intrinsic in the manufacturing process of rubber bushings at Lusida Rubber is the concept of high-quality engineering. The competent engineers in our team use cutting-edge technologies in combination with leading industry practices to make sure that the bushings we manufacture fully meet the specifications and performance requirements. Our design to production quality control system is based on reliability and constancy of details.

- Custom Solutions for Diverse Applications: We have a broad experience and manifold rubber bushing manufacturing capabilities which enable us to offer custom tailored solutions to each client according to the specific requirements. Our expertise spans a wide range of applications, from automotive and aerospace to marine and industrial. We can design bushings that will operate flawlessly under any kind of extreme conditions.

- Superior Materials for Durability and Longevity: Quality is our number one priority starting with the materials, which is why we use only the finest natural rubber compounds and elastomers in our production process. Materials are the key factor in product design. In this regard, materials are carefully chosen for their high resistance to wear and tear. Therefore, our rubber bushings stand the test of time and maintain their performance at the maximum level in the most severe operating conditions.

Key Features and Benefits

Improved vibration damping and noise insulation to make for smoother operation.

- Improved vibration damping and shock absorption will be designed to protect equipment and components.

- Reduced friction and wear extending service life and result in low maintenance costs.

- Customized designs to be fit in the event of special requirements and situations.

- Outstanding reliability and versatile operation in hostile surroundings.

- Adherence to the industry standard and regulations for quality purposes and reliability

Applications Across Industries

Lusida Rubber Products' rubber bushings are used in nearly all industries including:

- Automotive: From suspension systems and engine mounts to steering components as well.

- Aerospace: Landing system, control surfaces, aircraft interior.

- Marine: Perhaps that will mean factoring in engine mounts, fittings, hull damping system.

- Industrial: Machine stations, conveyor systems, heavy equipment, etc.

Commitment to Quality and Excellence

At Lusida Rubber Products, we are always passionate about giving the best quality and excellence of what we do in every aspect. We work closely with clients from beginning to end, with a focus to exceed expectations and even set new quality standards for rubber production worldwide.

Contact Us Today

See the difference of Lusida Rubber Products' high-quality bushings in your applications. Contact us today for more information about our products, customized solutions, and how we may help you achieve your goals for performance and reliability. Join us in our quest to bring you reliable and durable rubber products.