Injection Molding

Injection Molding Experts

Injection molding is a sophisticated manufacturing technique used in diverse industries to create precise and high-quality products. This process involves heating and compressing materials, such as rubber, within a chamber with a screw mechanism. Then, it injects the material into molds at high pressure, making it suitable for producing a wide range of products including automotive parts, medical devices, consumer electronics, packaging, and more.

Injection Molding Process

Material Preparation

The process begins with the selection of a suitable raw material, often in the form of plastic pellets or rubber granules.

These materials are loaded into a hopper, which feeds them into the injection molding machine.

Heating and Melting

Within the machine, the raw material is heated to a molten state. This is typically done using heaters and an auger system.

The auger, often referred to as a screw, rotates and conveys the material forward while applying heat to melt it completely.

Injection

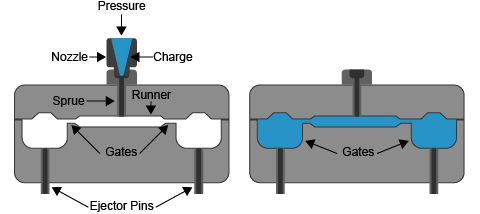

Once the material is in a molten state, it is injected into the mold cavity.

The mold is typically made of two halves, and the material is injected into the space between these halves.

Cooling and Solidification

As the molten material enters the mold, it begins to cool and solidify.

Cooling can be accelerated through the use of cooling channels within the mold.

The cooling time is carefully controlled to ensure the material solidifies properly and takes on the desired shape.

Ejection

After the material has solidified within the mold, the two halves of the mold are separated.

The newly formed part is ejected from the mold cavity using ejector pins or a knockout system.