Oil Seals

Oil Seals

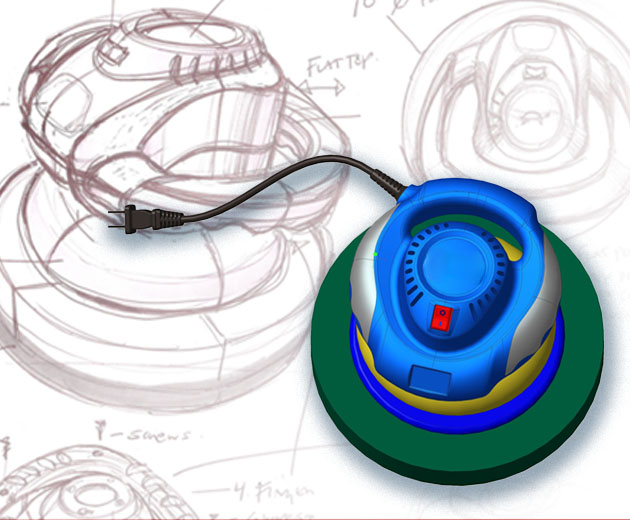

At Lusida, we pride ourselves on being at the forefront of innovation, bringing your product ideas to life with precision and creativity. Our dedicated team of designers, engineers, and creative minds collaborate seamlessly to transform concepts into tangible, market-ready products.

Seeking to elevate your current product? Our engineers stand ready to improve and adapt it to the evolving consumer landscape, ensuring continued relevance and market competitiveness.

Whether you're a startup looking to disrupt the market or an established company seeking to revitalize your product line, Lusida is here to help. Contact us today to discuss your project requirements and take the first step towards bringing your ideas to fruition. Let's innovate together!

We offer custom and standard automotive light solutions for cars, vans, SUVs and trucks.

Headlight Assembly

Fog Lights

Signal Lights

Tail Lights

Parking Lights

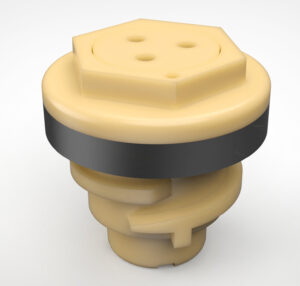

The rubber molding manufacturing operation is a serving process, which has proved to be extremely instrumental in coming up with a vast number of rubber-based materials that come in hand with our everyday things. Apart from vehicle parts and other goods, the rubber molding is considered as the main link anyhow between molding of rubber components and creation of the various design styles in rubber materials. While this article is a summary of it, we’ll take a deeper look into rubber molding types, working process, and other aspects.

Understanding Rubber Molding

Rubber molding is a production method in which you form a starting, appropriate material of raw rubber plastics into specific preformed shapes. It goes through the process of heating the rubber by heating and when it becomes malleable and then placing it under the pressure and then pressing it to mold cavity in order to achieve the desired shape. Additionally, the rubber is easily molded when it is heated and it will keep its molded form after cooling. This process is intended to result in a broad rubber products line, among which seals, gaskets, O-rings, and more (rubber products) fall.

Types of Rubber Molding

How Rubber Molding Works?

Rubber molding is a versatile and widely used manufacturing process that enables the production of a diverse range of rubber-based products. By understanding the different types of rubber molding and how the process works, manufacturers can efficiently create high-quality rubber components for various industries and applications. As technology advances, innovations in rubber molding continue to drive improvements in product design, performance, and efficiency.

A rubber seal is not quite the most interesting part of a machine component; however its function is highly important. Having the impression that it is comparable to the machinery’s purpose but in essence has the essential role of preventing leakage, contamination, and ensuring operational efficiency of the whole system, the rubber seal is vital.

Understanding types of Rubber Seals

You might know some seals like O-rings and gaskets, these are circular or square -shaped seals most commonly a synthetically derived rubber material; for example nitrile, silicone or elastomeric polymer, EPDM and Viton. Several functions can be associated with them such as the creation of a secured, non penetrable membrane at mating surfaces which results in the prevention of fluids or gas escape. Rubber seals are produced in an array of sizes and shapes to satisfy different requirements, which include but are not limited to plumbing fixtures, non-ferrous metal objects, and the like.

Functions of Rubber Seals

Benefits of Rubber Seals

While rubber seals may seem like small and unassuming components, their functions and benefits are anything but insignificant. From sealing joints and preventing leaks to enhancing reliability and ensuring compliance, seals are essential for the smooth operation of various mechanical systems across industries. As technology continues to advance, the demand for high-performance seals that can withstand extreme conditions and maintain operational efficiency will only grow, reaffirming the indispensable role of rubber seals in the modern world.

Rubber bushings may not be the most exciting part in a production line, but they have a great influence in various sectors like automotive suspensions and industrial hardware. Although they may appear simply as being inconspicuous ordinary cylindrical shapes of rubber, beneath that straightforward look there is a group of devices which are very crucial that they are useful for ensuring everything will be as it should be for each of the moving machines.

What Are Rubber Bushings?

Rubber bushings are used between two parts, most of the time metal, to reduce vibration and noise. Some examples where these are used are in suspension systems or the hoods of cars. These are normally manufactured together with a metal inner sleeve or core to hold bolts and shafts.

Applications of Rubber Bushings

Advantages of Rubber Bushings

Rubber bushings are indispensable components that provide essential functions in a wide range of mechanical systems. From automotive suspension systems to industrial machinery and beyond, these unassuming components play a crucial role in enhancing performance, durability, and comfort. With their ability to isolate vibrations, reduce noise, and withstand harsh operating conditions, rubber bushings offer numerous advantages that make them a preferred choice for engineers across various industries.

Through continuous innovation and refinement, rubber bushings will continue to evolve, meeting the ever-changing demands of modern engineering applications while maintaining their fundamental principles of reliability, versatility, and cost-effectiveness.

This Privacy Policy describes Our policies and procedures on the collection, use and disclosure of Your information when You use the Service and tells You about Your privacy rights and how the law protects You.

We use Your Personal data to provide and improve the Service. By using the Service, You agree to the collection and use of information in accordance with this Privacy Policy.

Types of Data Collected

Personal Data

While using Our Service, We may ask You to provide Us with certain personally identifiable information that can be used to contact or identify You. Personally identifiable information may include, but is not limited to:

Email address

First name and last name

Phone number

Company Address, State, Province, ZIP/Postal code, City

Usage Data

Usage Data is collected automatically when using the Service.

Usage Data may include information such as Your Device's Internet Protocol address (e.g. IP address), browser type, browser version, the pages of our Service that You visit, the time and date of Your visit, the time spent on those pages, unique device identifiers and other diagnostic data.

When You access the Service by or through a mobile device, We may collect certain information automatically, including, but not limited to, the type of mobile device You use, Your mobile device unique ID, the IP address of Your mobile device, Your mobile operating system, the type of mobile Internet browser You use, unique device identifiers and other diagnostic data.

We may also collect information that Your browser sends whenever You visit our Service or when You access the Service by or through a mobile device.

A cookie is a small file which asks permission to be placed on your computer’s hard drive. Once you agree, the file is added and the cookie helps us analyze web traffic.

Cookies help us provide you with a better website, by enabling us to provide the correct geographic information and to monitor which pages you find useful and which you do not. A cookie in no way gives us access to your computer or any information about you, other than the data you choose to share with us.

You can choose to accept or decline cookies. Most web browsers automatically accept cookies but you can usually modify your browser setting to decline. However this will affect the functionality of the websites you visit.

The Company may use Personal Data for the following purposes:

To process any orders you have made, either by email, telephone or online in order to comply with our obligations.

To provide and maintain our Service, including to monitor the usage of our Service.

To manage Your Account: to manage Your registration as a user of the Service. The Personal Data You provide can give You access to different functionalities of the Service that are available to You as a registered user.

For the performance of a contract: the development, compliance and undertaking of the purchase contract for the products, items or services You have purchased or of any other contract with Us through the Service.

To contact You: To contact You by email, telephone calls, SMS, or other equivalent forms of electronic communication, such as a mobile application's push notifications regarding updates or informative communications related to the functionalities, products or contracted services, including the security updates, when necessary or reasonable for their implementation.

We may use your information to contact you for marketing updates or research. We may contact you by email, phone or post.

To send you feedback or survey requests to help improve our services. We do this as a part of our legitimate interest to help make our products and services more relevant to you.

We may send you promotional materials informing you about the new products, special offers, promotions and company updates. You can opt out of this service any time by clicking UNSUBSCRIBE below our emails or emailing UNSUB to info@lusidarubber.com.

For other purposes: We may use Your information for other purposes, such as data analysis, identifying usage trends, determining the effectiveness of our promotional campaigns and to evaluate and improve our Service, products, services, marketing and your experience.

We may share Your personal information in the following situations:

With Service Providers: We may share Your personal information with Service Providers to monitor and analyze the use of our Service, to contact You.

For business transfers: We may share or transfer Your personal information in connection with, or during negotiations of, any merger, sale of Company assets, financing, or acquisition of all or a portion of Our business to another company.

With Affiliates: We may share Your information with Our affiliates, in which case we will require those affiliates to honor this Privacy Policy. Affiliates include Our parent company and any other subsidiaries, joint venture partners or other companies that We control or that are under common control with Us.

With business partners: We may share Your information with Our business partners to offer You certain products, services or promotions.

With other users: when You share personal information or otherwise interact in the public areas with other users, such information may be viewed by all users and may be publicly distributed outside.

With Your consent: We may disclose Your personal information for any other purpose with Your consent.

Retention of Your Personal Data

The Company will retain Your Personal Data only for as long as is necessary for the purposes set out in this Privacy Policy. We will retain and use Your Personal Data to the extent necessary to comply with our legal obligations (for example, if we are required to retain your data to comply with applicable laws), resolve disputes, and enforce our legal agreements and policies.

The Company will also retain Usage Data for internal analysis purposes. Usage Data is generally retained for a shorter period of time, except when this data is used to strengthen the security or to improve the functionality of Our Service, or We are legally obligated to retain this data for longer time periods.

Transfer of Your Personal Data

Your information, including Personal Data, is processed at the Company's operating offices and in any other places where the parties involved in the processing are located. It means that this information may be transferred to — and maintained on — computers located outside of Your state, province, country or other governmental jurisdiction where the data protection laws may differ from Your jurisdiction.

Your consent to this Privacy Policy followed by Your submission of such information represents Your agreement to that transfer.

The Company will take all steps reasonably necessary to ensure that Your data is treated securely and in accordance with this Privacy Policy and no transfer of Your Personal Data will take place to an organization or a country unless there are adequate controls in place including the security of Your data and other personal information.

You have the right to delete or request that We assist in deleting the Personal Data that We have collected about You.

Our Service may give You the ability to delete certain information about You from within the Service.

You may update, amend, or delete Your information at any time by signing in to Your Account, if you have one, and visiting the account settings section that allows you to manage Your personal information. You may also contact Us to request access to, correct, or delete any personal information that You have provided to Us.

Please note, however, that We may need to retain certain information when we have a legal obligation or lawful basis to do so.

Disclosure of Your Personal Data

Business Transactions

If the Company is involved in a merger, acquisition or asset sale, Your Personal Data may be transferred. We will provide notice before Your Personal Data is transferred and becomes subject to a different Privacy Policy.

Law enforcement

Under certain circumstances, the Company may be required to disclose Your Personal Data if required to do so by law or in response to valid requests by public authorities (e.g. a court or a government agency).

Other legal requirements

The Company may disclose Your Personal Data in the good faith belief that such action is necessary to:

· Comply with a legal obligation

· Protect and defend the rights or property of the Company

· Prevent or investigate possible wrongdoing in connection with the Service

· Protect the personal safety of Users of the Service or the public

· Protect against legal liability

Security of Your Personal Data

The security of Your Personal Data is important to Us, but remember that no method of transmission over the Internet, or method of electronic storage is 100% secure. While We strive to use commercially acceptable means to protect Your Personal Data, We cannot guarantee its absolute security.

We may update Our Privacy Policy from time to time. We will notify You of any changes by posting the new Privacy Policy on this page.

We will let You know via email and/or a prominent notice on Our Service, prior to the change becoming effective and update the "Last updated" date at the top of this Privacy Policy.

You are advised to review this Privacy Policy periodically for any changes. Changes to this Privacy Policy are effective when they are posted on this page.

If you have any questions about this Privacy Policy, You can contact us:

· By email: info@lusidarubber.com

Rubber molding is a unique manufacturing operation that is very complex and has proved to be an integral feature in modern manufacturing. With rubber, and the vast amount of products one can make from it, there is no equal in terms of its versatility, moldability, and durability because a great variety of rubber components are formed within it and used across industries. The intensive procedure of Lusida Rubber Products commemorates the widespread uses, intricacies, and exceptional value of rubber molding in the global marketplace, which is helped by innovation and commitment.

Rubber molding finds widespread applications across various industries: